Sponsored by The Tourism Association of Central Region in Fukushima Prefecture

The Brewery

Niida-Honke Brewery is over 300 years old, and has seen its share of change. Originally founded in 1711, it has seen eighteen generations of dedicated head brewers work to create their ideal sake, one that is healthy, sustainable and organic. Located only twenty minutes by car from Koriyama Station in Fukushima Prefecture the brewery is renowned for its delicious sake, having won several awards. But what makes Niida-Honke Brewery truly unique is their mission to create sustainable organic sake, “Shizenshu,” using only natural ingredients and a traditional brewing process.

100 Percent Natural

In 2011 the brewery decided to take a step in a more sustainable direction by using only organically grown rice in the sake making process. In 2013 they decided to take their ideals a step further and stopped adding lactic acid during the brewing process, at the same time they began to use an entirely natural yeast starter. In 2014 they made another big leap and stopped using sediment removers, making them the first brewery to create a brand of sake from entirely organic ingredients.

These days the brewery grows and harvests its own rice, completely pesticide and chemical fertilizer free, using methods such as hand weeding and tadpole shrimp to maintain the rice paddies.

All of the water used in their sake is natural spring or well water, which is collected from land owned by the brewery. This water is used in every step of the sake making process, from washing the rice to cleaning the tanks.

The company also strives to reduce its environmental impact by cutting down on packaging, and reusing returnable bottles.

Take a look at their website here: https://kinpou.co.jp/english.html to get a better understanding of just how much effort and love and commitment goes into the sake made at Niida-Honke Brewery.

The Process

Making sake is a complicated process if you are unfamiliar with the steps needed to create alcohol from natural ingredients.

Because sake is made from rice, this is where the process begins.

At Niida-Honke Brewery, rice is grown on their own land, by their own brewers and farmers. Once the rice is harvested they transfer it to the rice mill where it undergoes the first step, polishing.

- Polishing or milling as it is more commonly called involved removing the outer layer of rice in order to expose the starchy core. For sake, usually the more milled the rice is, the better the sake will be, and often companies will remove 30 to 50 percent of the outer layers in order to create a more aromatic sake product.

- The next step is washing the rice; this is down to begin the process of introducing moisture to the grains. Moisture is important for later stages of the brewing process. After the rice has been washed it is then soaked, in order to fully prep it for the next process, steaming.

- After the rice is soaked and washed it is time to steam. The rice is laid out in a large strainer, and steamed from below. Each of these steps is precisely timed to create the perfect ingredient.

- The rice must then be cooled in a large rice cooler. This step is important because the rice must be cool and dry on the outside, but still moist on the inside.

- The next step is to make “koji rice.” Koji is a type of mold, which helps to change the starch from the rice into sugar for the yeast to feed on. Without koji the yeast would be unable to change the starch into alcohol, and so this is a very important part of the sake making process. “Koji Rice” is made by spreading the freshly steamed and cooled rice onto tables in a very warm room. The steamed rice is then sprinkled with the kojikin (mold) and left to sit for around four days. This gives the koji time to penetrate to the moist center of the grains of rice, and grow.

- From here a small batch of sake is made using the koji rice, yeast and water. This batch is called a yeast starter, because the yeast content is especially high. In Japanese this is called “Moto” or “Shubu.”

- Now it is time for the main mash. In a large brewing tank, the yeast starter, rice, water, and koji rice are all added together. This is done three times over four days to allow the ingredients to settle. After the third addition, the mash is left to ferment.

- Pressing (Fukuro-Zuri) This step is a more traditional method, although the brewery does also use the newer methods of pressing as well. At this point the alcohol must be streamed. Using the “Fukuro-Zuri” or “Hanging Bag” method the mash is poured into bags and … you guessed it…. hung from a pole in order to separate the solids from the liquids and to get sake.

- At this point the sake is safe to drink, although further pasteurization may be required by heating the sake to kill any remaining enzymes.

And there you have it; the main steps in creating original sake.

The Products

Niida-Honke Brewery sells and distributes a variety of different sake brands and types, and took home the first place prize for their Odayaka Junmai-Daiginjo Sake in 2013 at the Fukushima Prefecture Sake Competition. For a full list of sake brands be sure to check out their website.

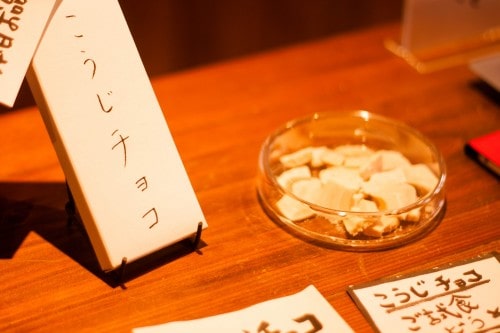

But they don’t only sell sake. They also sell a variety of other fermented foods made from the mash or sake lees, which are separated from the alcohol.

The Tour

I had the opportunity to take a tour of the Niida-Honke Brewery, and it was a very rewarding experience. My guide spoke excellent English and gave me an English pamphlet and brochure to help explain the more difficult jargon.

After donning a white robe, sandals and a hair net I was led through every section of the brewery and my guide explained in great detail the process of brewing sake. I was able to feel just how hot the koji room was, and prayers made to the sake god. I was able to watch and take photos of the hukuro zuru process, and perhaps the most amazing experience by far, was a taste of the freshly pressed sake from the head brewer himself!

I highly recommend taking a tour of this wonderful brewery. They have a strong commitment to the environment, and a desire to create a wonderful experience for their guests.

If you are interested in a tour please contact them to make an appointment. The brewery is only open during brewing season (winter time).

If you do visit in the summer and want to experience this brewery be sure to check out their organic rice growing workshops, where you can experience hands on rice planting, weeding, and harvesting, plus enjoy a taste of their famous sake.

Access

From Tokyo:

Take the Tohoku Shinkansen to Koriyama Station

From Koriyama Station:

Take a taxi to “Niida Honke” you can show your taxi driver this name/address as below:

It should cost about 3,400 yen.

Make a Reservation

Please email them if you like to visit: info@kinpou.co.jp

Official website: here

[cft format=0]

No Comments yet!